Home ≫Sterilization >Disinfectors >Washer Disinfector SMI-107

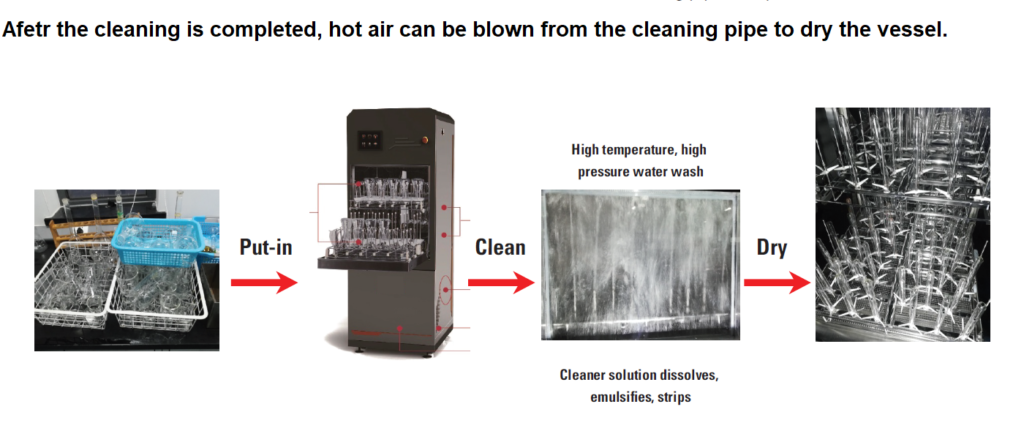

Washer disinfector is also called Lab automatic glassware washer. The whole process is water inflow, spray scouring, washing with cleaner, cleaning, heating, drainage, drying, etc., and all are automatically carried out. As long as the program is set up, the intermediate process does not require any manual operation. After the vessel is placed in the automatic cleaning, the vessel can be used normally.

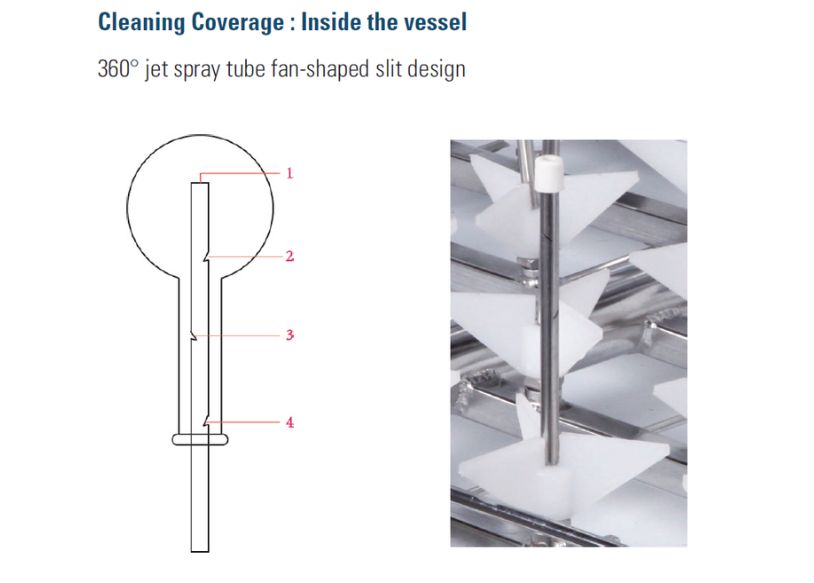

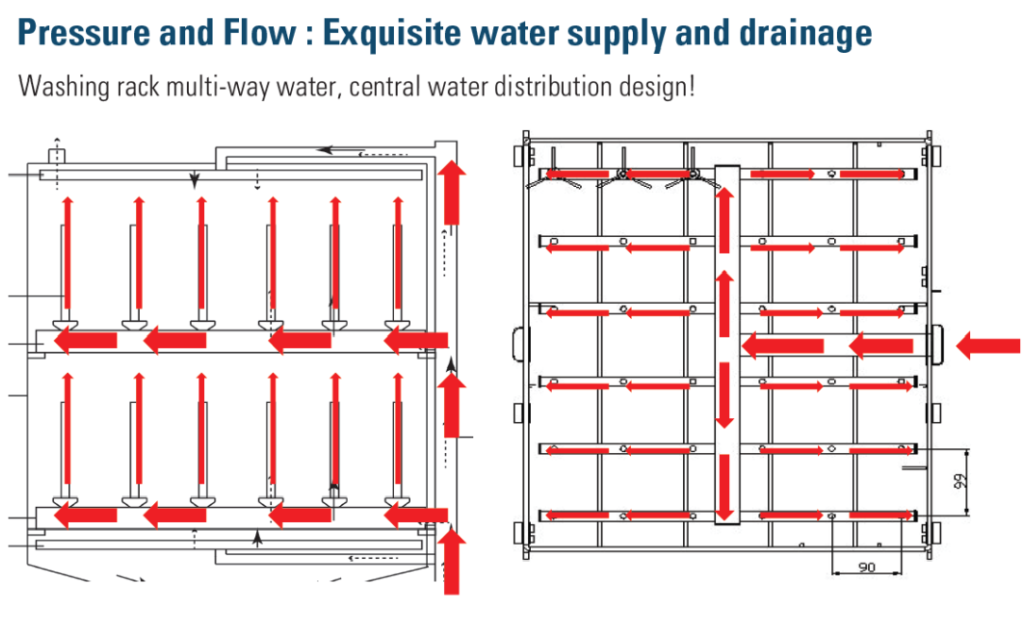

The disinfector consists of three rotary spray arms. The design and location of the arms ensure that every surface of the loaded material is uniformly cleaned. The chamber of the disinfector has rounded corners to prevent dirty breeding grounds. The rotation of the arm is activated by the water pressure which eliminates any mechanical drive system.

The inner and outer surfaces of various types of vessels in the laboratory are sprayed and washed by the mechanical scouring force of the high temperature and high pressure water in the cleaning chamber. At the same time, combined with the cleaner to dissolve, emulsify and peel off the contents of the vessel, thereby achieving clean cleaning of the inner and outer surfaces of the vessel.

Our disinfector comes with a range of standard accessories for different surgical appliance & kidney trays, bottles, tubings & instruments.

The machine is incorporated with an automatic detergent dozing system to doze the required amount of detergent in the rinsing water.

The unit is incorporated with an in built electric water heater. The hot water here is used to disinfect the loaded material at a temperature of 95°C (i.e. hemodisinfection) after thorough cleaning & rinsing.

The disinfector has a microprocessor-controlled operation. The operating console is provided with an electronic unit with LEDs for easy operation and monitoring of the process. Up to three pre-programmed processes give the user fantastic flexibility for cleaning and disinfecting a wide range of load configurations.

As in hospitals, where hot water is not available, the disinfector is equipped with an electric heating system. This heats the water to a temperature of 90°C for higher cleaning efficiency.

T he outer body is fabricated out of non-corrosive 304 Grade Stainless steel/PVC Moulded. The inner chamber is made of Stainless Steel with rounded corners for easy cleaning and to avoid contamination. The door is provided with a high quality gasket. All piping and valves are of Stainless steel construction.

The disinfector is a simple, easy-to-use machine. The machine requires no installation. It has to be connected to the different supply lines and the drain line to start the operation.

Custom built design can also be manufactured on confirmed order.

Model No.: | SMI-107 | SMI-107-01 | SMI-107-02 |

Capacity | 220L | 320L | 420L |

Water Consumption/Cycle | 22L | 24L | 26L |

Inlet Water Pressure | 0.03 to 0.8Mpa | ||

Noise | <60bB | ||

Material | Stainless steel | ||

Overall Power Consumption | 17 KW | ||

Power Consumption Water Washing | 1.5 KW | ||

Power Consumption Water Heating | 15 KW | ||

Power Consumption Drying | 3.6 KW | ||

Power Supply | 380V, 50Hz (Standard); 110V, 60Hz (Optional) | ||

Washing chamber Size (W X D X H) mm | 600 X 629 X 658 | 600 X 629 X 820 | 688 X 700 X 703 |

External Size (W X D X H) mm | 960 X 800 X 1880 | 960 X 800 X 2030 | 1100 X 930 X 2085 |

Package Size (W X D X H) mm | 1200 X 1000 X 2200 | 1200 X 1000 X 2350 | 1300 X 1100 X 2300 |

Gross Weight (Kg) | 360 | 370 | 460 |

Product Brochure Link here