Home ≫Ultra Low Temp. >Deep Freezer -86°C > Cascade ULT Freezer >Cascade ULT Freezer SMI-165EJ-1007

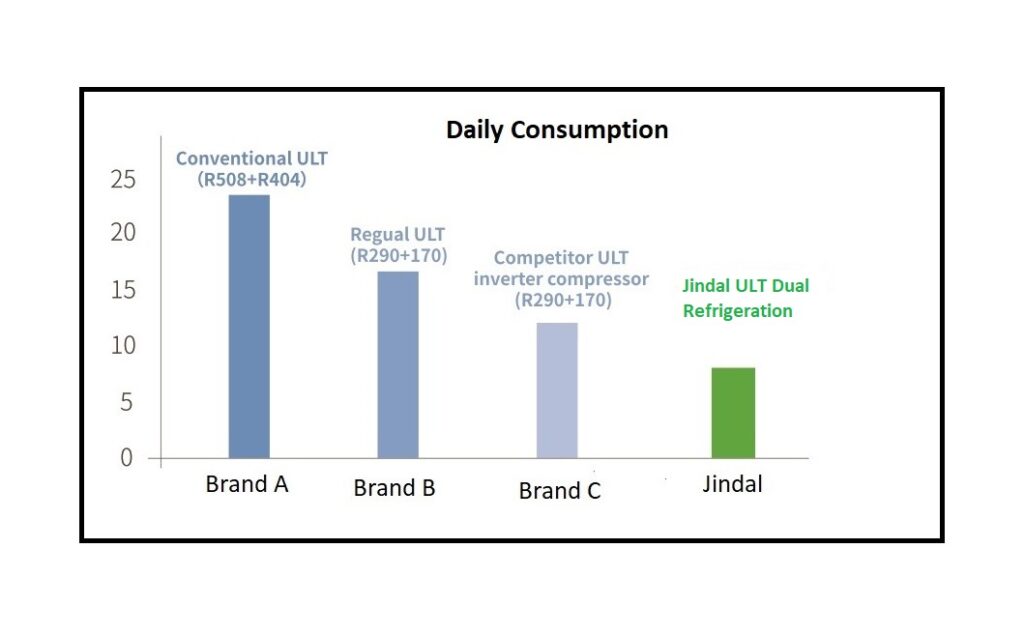

The Jindal ULT freezer features a two-stage cascade cooling technology using natural hydrocarbon refrigerants, R290 and R170. Its inverter compressors are programmed to optimize energy efficiency during long-term preservation and to enable rapid temperature recovery when the door is frequently opened, ensuring specimen viability.

The Jindal ultra-low temperature freezer is designed for a wide range of applications, functioning effectively as a laboratory, medical, or deep freezer. It is well-suited for hospitals, public health and disease control organizations, research centers, academic institutions, the electronics and biotechnology industries, military facilities, and deep-sea fishing operations.

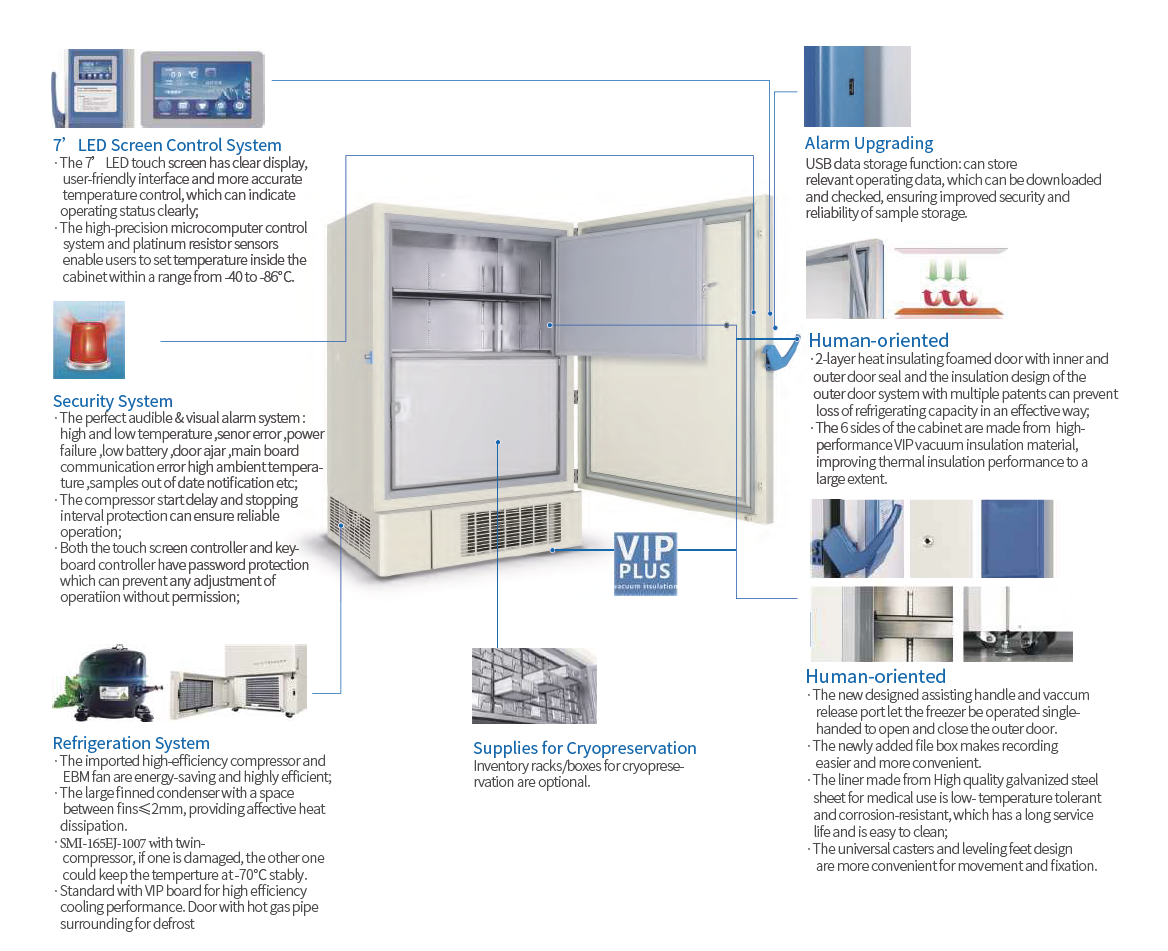

High-efficiency frequency conversion compressors automatically adjust operating power based on the heat load, resulting in significant energy savings.

An ergonomic handle, smooth sliding track, and high-precision pressure relief valve make door operation easy and effortless

Three adjustable dividers create four storage layers for organized sample placement. Two inner doors help minimize frost buildup during door openings

The interior is made of durable, easy-to-clean stainless steel (SUS304)

The unit is equipped with four heavy-duty casters and two leveling feet, allowing for easy mobility and stable positioning

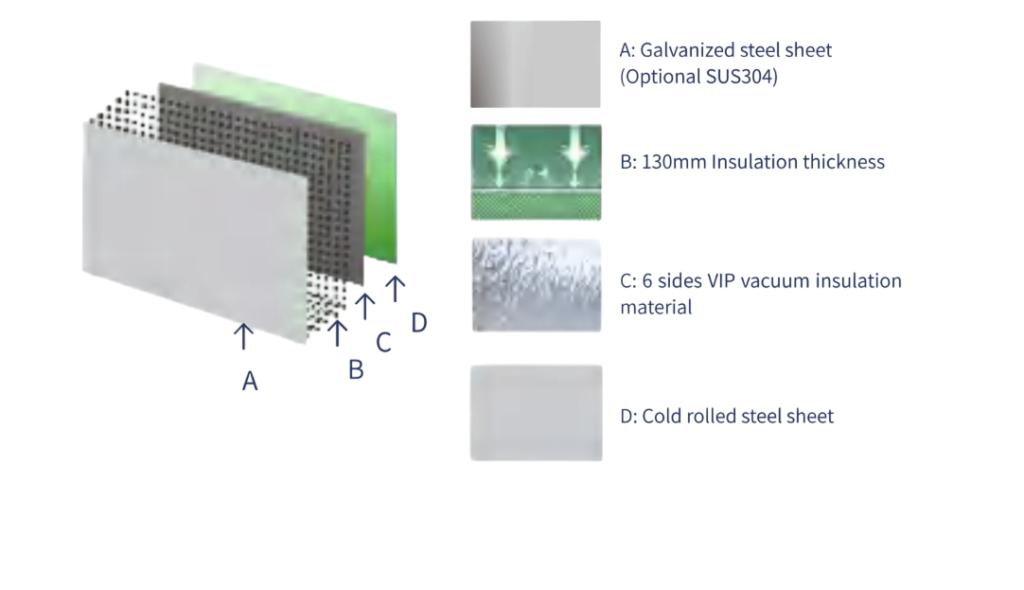

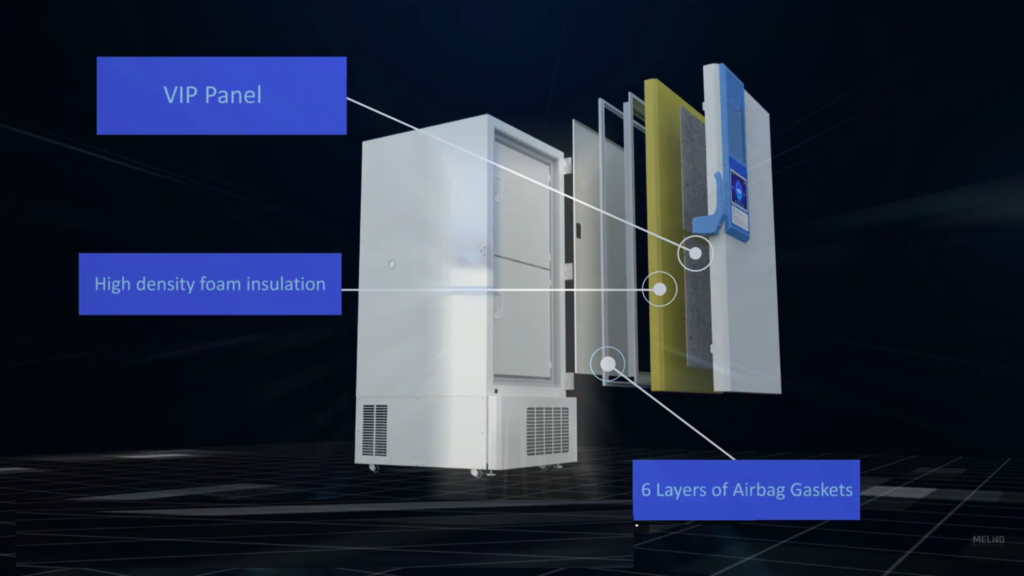

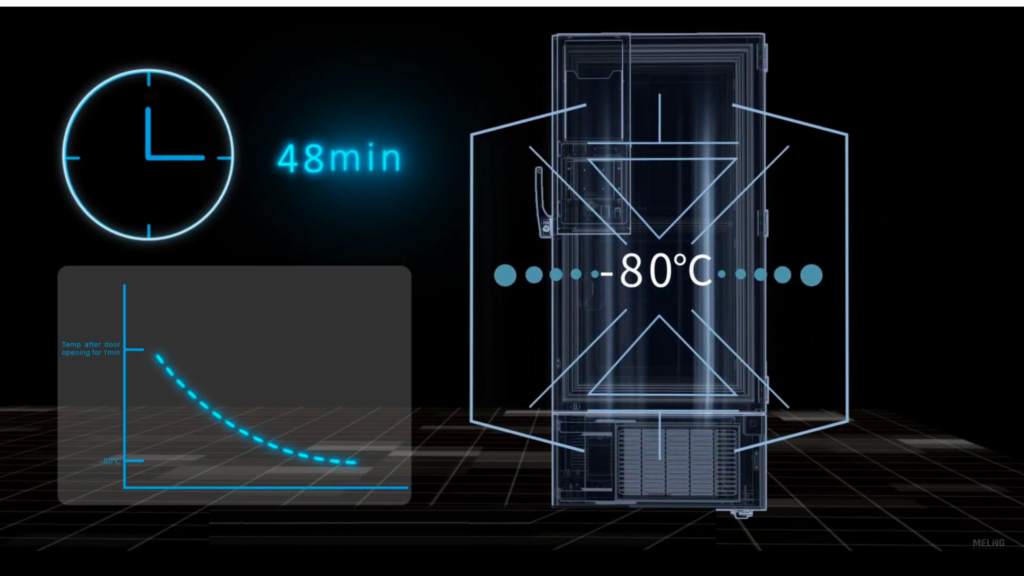

The combination of 130mm CFC-free PU foam and high-quality vacuum insulated panels provides superior insulation, preventing rapid temperature increases and ensuring low energy consumption. The design of foam inner doors, built-in vacuum insulation board and triple independent silicone sealing strip design make the insulation performance excellent.

The ULT freezer uses natural green gases as refrigerants to meet safety requirements for usage. These natural hydrocarbon refrigerants are SNAP-compliant according to U.S. regulations. Additionally, this is supported by European Union regulation (EU-517/2014). The foaming agents used during manufacturing are fully controlled to ensure they are environmentally friendly.

The intelligent control of the inverter compressor optimizes its running speed based on the conditions. When the inverter compressor is operating normally, it runs for longer periods than a conventional compressor but at a minimal speed. This reduces power consumption and helps maintain a stable freezer temperature. When the door is opened, the compressor adjusts its speed to quickly bring the temperature inside the freezer back down to the set value before resuming its normal cycle.

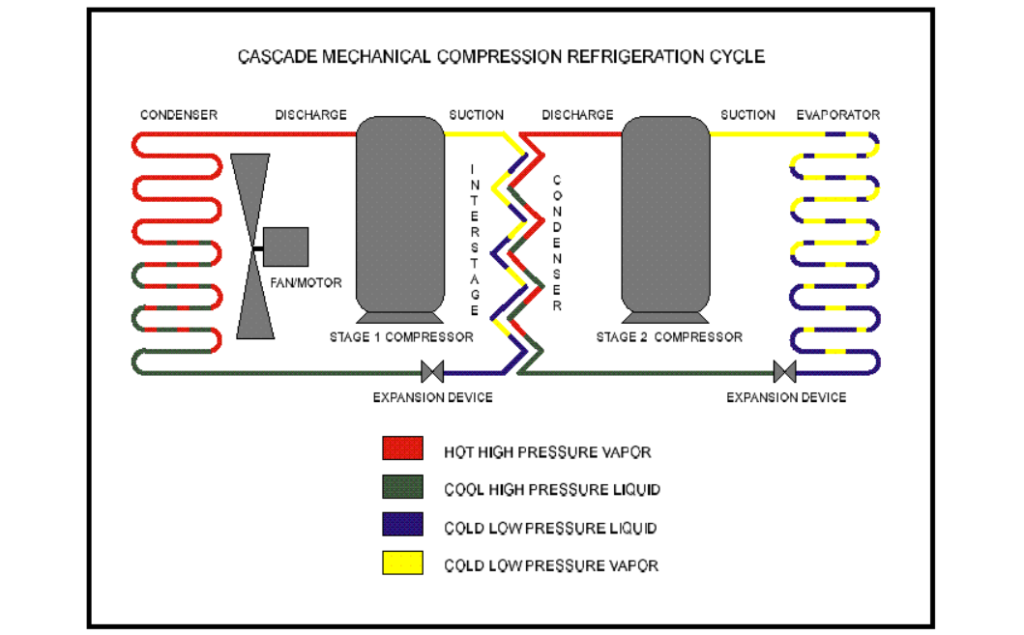

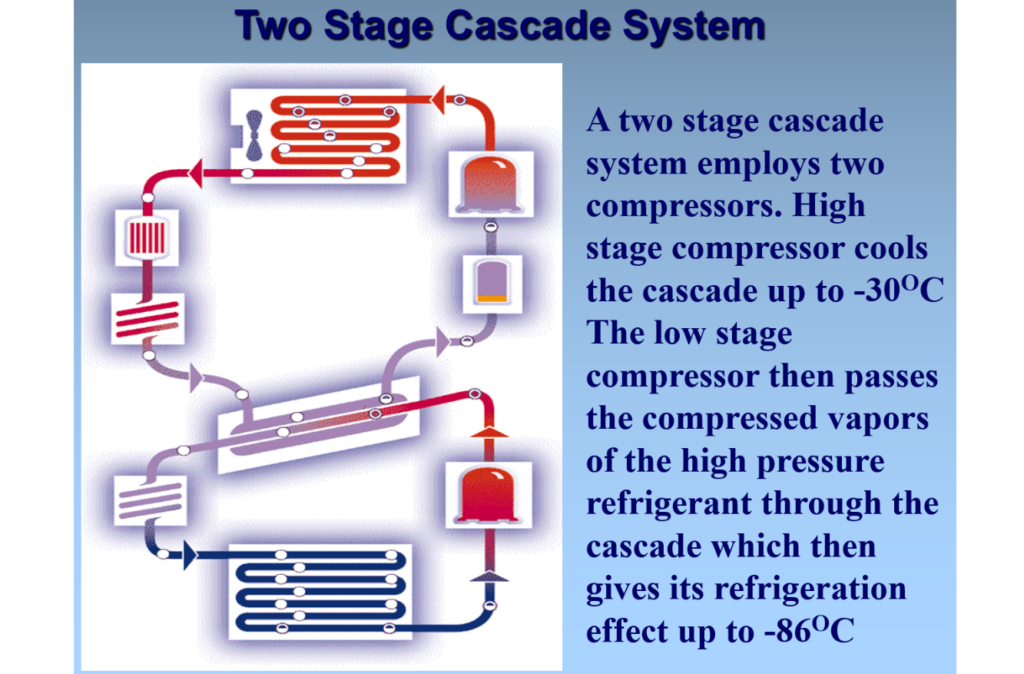

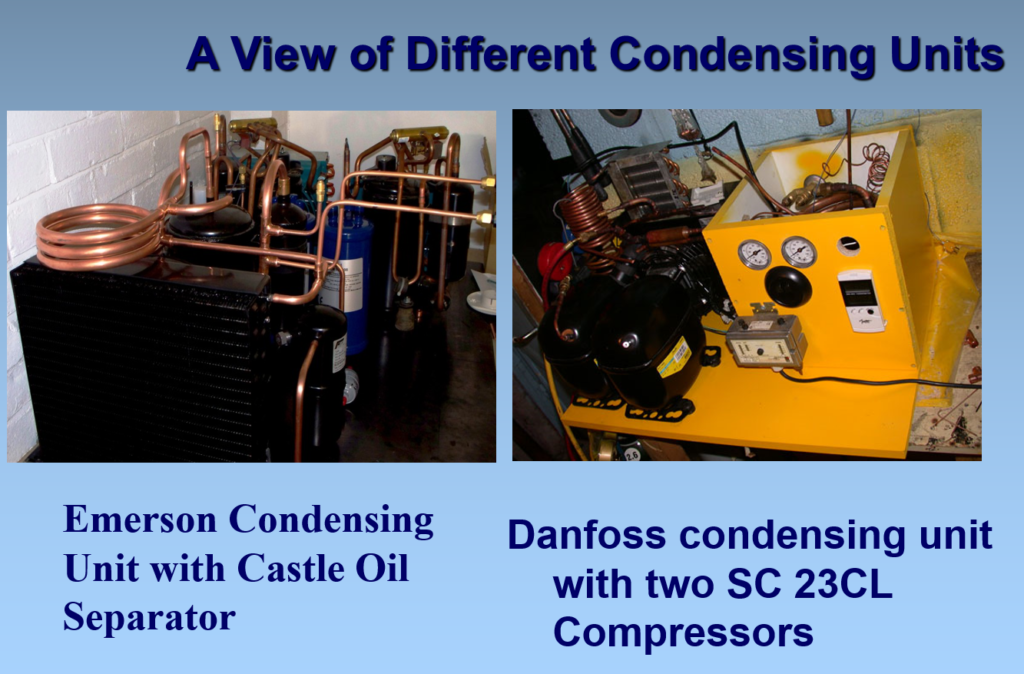

The cascade system consists of two independent refrigeration cycles: a low-stage cycle and a high-stage cycle. These cycles are connected through a cascade condenser. The high-stage and low-stage systems operate separately using different refrigerants, with the evaporator of the first cycle cooling the condenser of the second cycle. The first stage lowers the temperature to -40°C, while the second stage further reduces it to -86°C using natural refrigerants.

Two-stage cascade refrigeration system

Inverter technology with dual inverter compressors

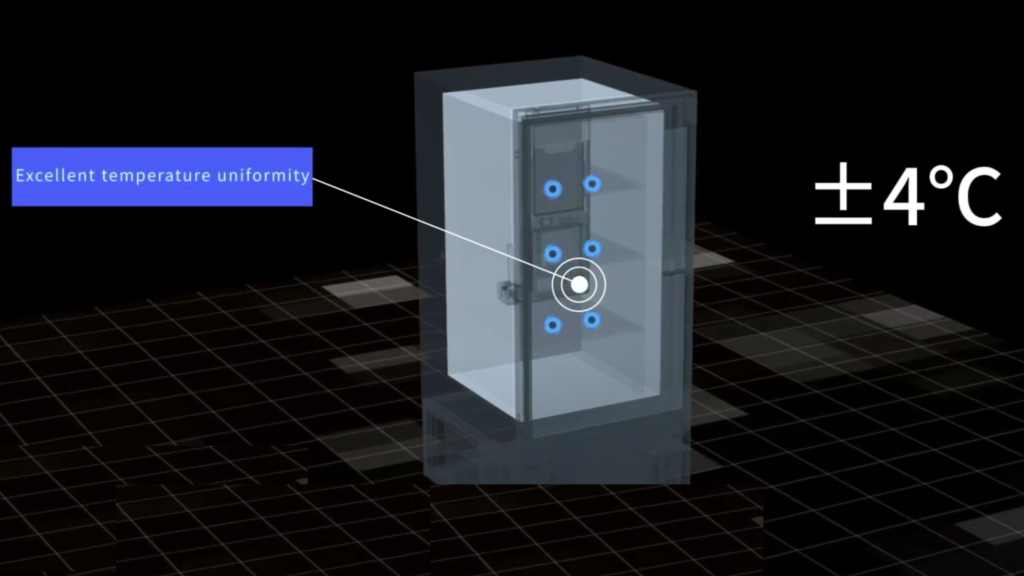

±4°C temperature uniformity

Rapid temperature pull-down to -80°C within 5 hours

Daily energy consumption: 8.7 kWh

High-definition, user-friendly control panel allows temperature setting from -40°C to -86°C with 1°C digital display accuracy

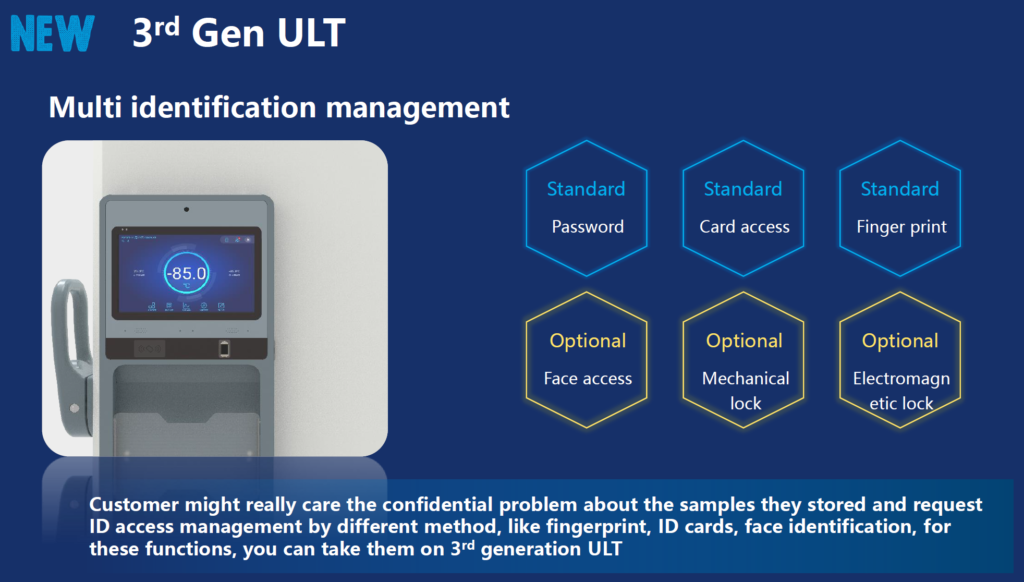

Security features include a lockable door, keyboard lock, and password protection to prevent unauthorized access

Three adjustable stainless steel shelves, inner door, and double silicone gasket seal for improved insulation and sample protection

Chart recorder

CO₂ backup system

Freezer racks, boxes, and tubes

Remote alarm system

Modbus protocol for data transfer

Card or fingerprint access

Compliance with 21 CFR Part 11 regulation

Model | SMI-165EJ-1007 |

Capacity(L) | 1007 |

Internal size(W X D X H)mm/Inch | 1022 X 696 X 1378 |

External size(W X D X H)mm/Inch | 1362 X 1025 X 1994 |

NW/GW(Kgs) | 426 |

Temperature range | -40 to -86℃ |

Ambient temperature | 16-32℃ |

Cooling performance | -86℃ |

Climate class | N |

Controller | Microprocessor |

Display | 10‘’HD Intelligent touch screen |

Compressor | 2 Nos. |

Cooling method | Direct cooling |

Defrost mode | Manual |

Refrigerant | High stage: R290, Low stage: R170 |

Insulation thickness(mm) | L/R:130,B:130 |

External material | Cold rolled steel |

Inner material | Stainless steel |

Shelves | 3(stainless steel) |

Access port | 2pc. Ø 25 mm |

Casters | 4+(2 leveling feet) |

Data Logging/Interval/Memory capacity | USB/Record every 5 minutes / 10 years |

Backup battery | Yes |

Temperature | High/Low temperature, High ambient temperature |

Electrical | Power failure , Low battery, Battery power detection failure |

System | Sensor failure, Communication error, Condenser overheating, Door ajar |

Freezer rack model | SS 304-552B-CT;ZKML304-652B-CT |

Freezer rack/box (quantity) | 14+14/770 |

Product Brochure Link here